SolidDrops: Saudi Arabia’s Premier ESD Flooring Solutions Provider

In the world of sensitive electronic manufacturing, healthcare facilities, and data centers, electrostatic discharge (ESD) protection is not merely a recommendation—it’s an absolute necessity. At SolidDrops, we pride ourselves on being Saudi Arabia’s leading applicator and supplier of comprehensive ESD flooring solutions, including anti-static, static-dissipative, and conductive flooring systems. Our expertise in the application and distribution of high-quality ESD flooring materials has established us as the trusted partner for businesses across the Kingdom seeking to protect their valuable equipment and ensure operational continuity.

Understanding ESD Flooring: The Critical Foundation for Electronic Safety

Electrostatic discharge occurs when two differently charged objects come into contact, potentially causing damage to sensitive electronic components. This invisible threat can result in equipment failure, compromised data integrity, and significant financial losses. ESD flooring systems serve as the first line of defense against these risks, effectively channeling static electricity safely to ground before it can accumulate to dangerous levels.

The three primary categories of ESD flooring we specialize in include:

Anti-Static Flooring: Prevention-Focused Protection

Anti-static floors are engineered to prevent the initial generation of static electricity. These sophisticated flooring systems incorporate special materials that inhibit the triboelectric charging process—the physical separation of positive and negative charges that occurs when two materials contact and then separate. Our premium anti-static solutions maintain resistance measurements between 1×10^9 and 1×10^12 ohms, creating an environment where harmful static buildup is significantly reduced.

Static-Dissipative Flooring: Controlled Discharge Management

When static charges do develop, static-dissipative floors excel at controlling their flow to ground at a manageable rate. These systems feature resistance readings between 1×10^6 and 1×10^9 ohms, providing the ideal balance between conductivity and safety. Our high-performance static-dissipative flooring ensures that any accumulated charges dissipate gradually, preventing both harmful discharges and safety risks to personnel.

Conductive Flooring: Rapid Grounding for Maximum Protection

For environments with extremely sensitive equipment or explosive materials, conductive flooring offers the highest level of ESD protection. With resistance measurements between 2.5×10^4 and 1×10^6 ohms, these specialized floors rapidly channel static electricity to ground. SolidDrops’ superior conductive flooring solutions deliver uncompromising protection in the most demanding applications, from semiconductor manufacturing to military installations.

SolidDrops: Comprehensive ESD Flooring Materials Portfolio

We take pride in our extensive selection of high-quality ESD flooring materials, carefully curated to meet diverse industry requirements and performance specifications. Our comprehensive product lineup includes:

ESD Vinyl Flooring: Versatile Excellence

Our ESD vinyl flooring combines outstanding electrostatic protection with exceptional durability and aesthetic appeal. These versatile systems feature:

- Consistent electrical performance throughout the product lifetime

- Superior resistance to heavy traffic and rolling loads

- Minimal maintenance requirements

- Extensive color and pattern options for design flexibility

- Excellent chemical resistance properties

The homogeneous construction of our premium ESD vinyl ensures that electrical properties remain consistent even as the floor wears, providing long-term protection and value.

ESD Rubber Flooring: Unmatched Resilience

For applications demanding extraordinary durability and comfort, our ESD rubber flooring delivers exceptional performance. Key benefits include:

- Superior impact and indentation resistance

- Enhanced ergonomic properties reducing fatigue

- Natural sound-dampening characteristics

- Exceptional longevity even in challenging environments

- Sustainable and environmentally responsible composition

Our high-performance rubber ESD solutions withstand the most demanding industrial conditions while maintaining consistent electrical properties throughout their extended service life.

ESD Epoxy Flooring: Seamless Protection

When a monolithic, seamless surface is required, our ESD epoxy flooring systems provide the ideal solution. These advanced formulations offer:

- Completely joint-free installation eliminating dust traps

- Customizable electrical properties for precise performance

- Outstanding chemical and stain resistance

- Ability to incorporate corporate branding elements

- Exceptional bond strength to properly prepared substrates

The professional-grade ESD epoxy systems we supply create virtually impermeable surfaces that maintain consistent electrical performance while resisting potential contamination.

ESD Polyurethane Flooring: Advanced Performance

For the most demanding applications, our ESD polyurethane flooring represents the pinnacle of performance technology, delivering:

- Superior UV stability for consistent appearance

- Exceptional chemical resistance properties

- Enhanced flexibility reducing cracking potential

- Extended service life even in harsh environments

- Advanced thermal shock resistance

These high-technology ESD polyurethane systems provide the ultimate combination of protection, durability, and aesthetic value for critical environments.

Premium Brands for Uncompromising Quality

At SolidDrops, we understand that the foundation of exceptional flooring performance lies in the quality of materials used. This commitment to excellence drives our partnership with the world’s leading manufacturers of ESD flooring components. Our principal supplier relationships include:

Sika: Engineering Excellence

As authorized distributors of Sika ESD flooring solutions, we provide access to some of the most advanced epoxy and polyurethane systems available globally. Sika’s renowned research and development capabilities ensure that their ESD products incorporate the latest technological innovations.

Master Builders: Performance Leadership

Our partnership with Master Builders allows us to offer their comprehensive range of high-performance ESD flooring solutions, known for exceptional durability and consistent electrical properties throughout their service life.

BASF: Chemical Engineering Mastery

The BASF ESD flooring systems we supply leverage the company’s unparalleled expertise in chemical engineering to deliver products with precisely controlled electrical properties and outstanding chemical resistance.

Fosroc: Global Expertise

Our relationship with Fosroc provides our clients with access to their specialized ESD solutions, incorporating global expertise and regional formulations optimized for Saudi Arabia’s unique environmental conditions.

Jotun: Aesthetic Excellence

For applications where appearance is as important as performance, the Jotun ESD flooring products we supply combine superior protection with exceptional aesthetic qualities and color stability.

DCP: Local Knowledge

Our partnership with DCP allows us to offer ESD solutions specifically engineered for the unique challenges of the Saudi Arabian environment, with formulations optimized for local conditions.

SolidDrops: Beyond Product Supply

What truly differentiates SolidDrops in the Saudi Arabian market is our comprehensive approach to ESD flooring implementation. We don’t simply supply materials—we provide complete solutions including:

- Thorough site assessment and requirement analysis

- Detailed specification development aligning with international standards

- Expert installation by certified application teams

- Comprehensive testing and verification of electrical performance

- Detailed maintenance programs ensuring long-term performance

- Ongoing technical support throughout the system lifecycle

Our holistic approach ensures that every ESD flooring installation we undertake delivers optimal protection, durability, and value for our clients.

The Critical Importance of Professional Application

Even the highest quality ESD flooring materials can fail to perform properly if not installed correctly. Our specialized application teams possess the expertise, experience, and certification necessary to ensure flawless implementation of these sophisticated systems. Our installation methodology includes:

- Meticulous substrate preparation ensuring proper adhesion

- Precision installation of grounding systems and conductive elements

- Careful control of environmental conditions during application

- Thorough testing protocols verifying electrical performance

- Comprehensive documentation of the installation process

This rigorous approach guarantees that the ESD flooring systems we install perform to specification from day one and maintain their protective properties throughout their service life.

At SolidDrops, we remain committed to advancing the standard of ESD protection in Saudi Arabia through our uncompromising focus on quality, expertise, and service excellence. Our comprehensive understanding of electrostatic discharge risks and mitigation strategies positions us as the premier provider of complete ESD flooring solutions for organizations requiring absolute reliability in their static control measures.

Contact SolidDrops today to discover how our industry-leading ESD flooring expertise can protect your valuable assets and ensure operational continuity in your sensitive environments.

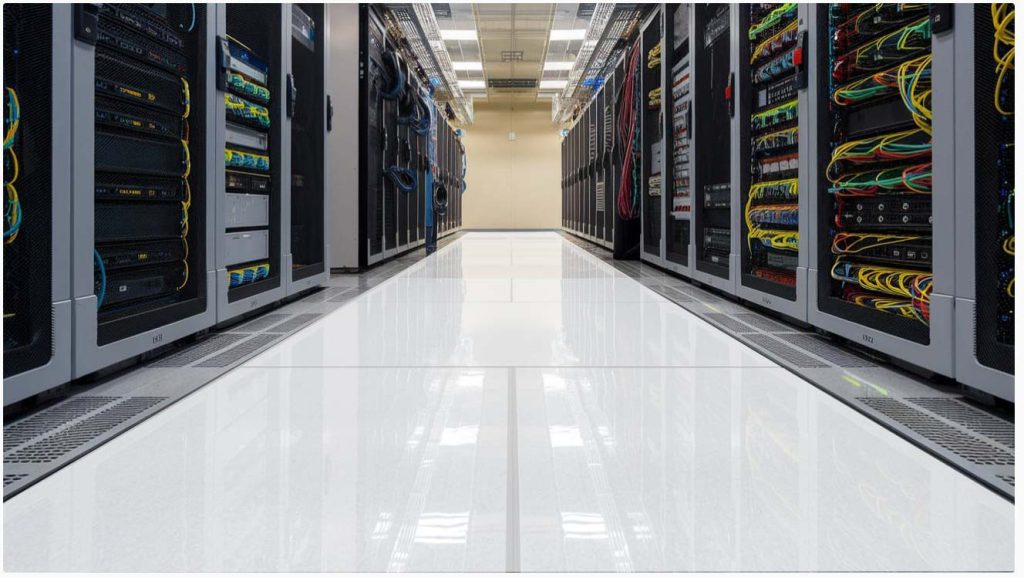

Soliddrops is recognized as a leading supplier and applicator in Saudi Arabia for ESD (Electrostatic Discharge) flooring solutions. They offer a comprehensive range of products, including ESD vinyl, ESD rubber, ESD epoxy, and ESD polyurethane, sourced from top brands such as Sika, Masterbuilders, Basf, Fosroc, Jotun, and DCP. These flooring systems are critical in environments where static electricity can damage sensitive equipment or create safety hazards, such as electronics manufacturing facilities, laboratories, and data centers.

Why Choose Soliddrops?

Soliddrops stands out in Saudi Arabia for its expertise in supplying and applying these ESD flooring solutions. Whether you need the durability of ESD polyurethane, the flexibility of ESD rubber, or the seamless finish of ESD epoxy, their focus on premium brands ensures quality and performance. The right ESD flooring depends on factors like static control needs, traffic levels, chemical exposure, and design preferences—Soliddrops offers tailored options to meet every requirement.

Types of ESD Flooring

ESD flooring is designed to manage electrostatic discharge, and Soliddrops provides several types tailored to specific needs:

- Anti-static Floor

- Purpose: Reduces the generation of static electricity but does not dissipate it quickly.

- Use: Ideal for areas where basic static control is sufficient but not critical for highly sensitive electronics.

- Appearance: Often available in tiled or sheet forms, with smooth surfaces in colors like gray or blue.

- Anti-static Floor

- Static-dissipative Floor

- Purpose: Allows static charges to dissipate at a controlled rate, with a resistance between 1.0 × 10^6 and 1.0 × 10^9 ohms.

- Use: Suitable for environments handling sensitive electronic components, preventing rapid discharges that could cause damage.

- Appearance: Can be seamless coatings or tiles, often with a subtle texture, in shades like light gray or patterned designs.

- Static-dissipative Floor

- Conductive Floor

- Purpose: Rapidly dissipates static charges, with a resistance of less than 1.0 × 10^6 ohms.

- Use: Perfect for high-risk settings like clean rooms or areas with explosive materials.

- Appearance: Typically seamless and glossy, available in customizable colors or with safety markings.

- Conductive Floor

- ESD Floor

- Purpose: A general term for floors that control electrostatic discharge, including static-dissipative and conductive options.

- Use: Transfers static charges safely to an earthing point, protecting sensitive devices across various industries.

- Appearance: Varies by material—vinyl, rubber, epoxy, or polyurethane—offering flexibility in design and function.

- ESD Floor

Visual Description of ESD Flooring

Although I cannot generate images directly, here’s how these floors typically look:

- ESD Vinyl: Installed as square tiles or rolls, about 2-3 mm thick, with a smooth or textured surface. Colors like gray, blue, or checkerboard patterns are common.

- ESD Rubber: Similar to vinyl but with more cushioning, featuring a hammered or smooth finish, often in darker shades like gray or black.

- ESD Epoxy: A seamless, liquid-applied coating over concrete, curing to a glossy or matte finish. It can include decorative flakes or color quartz for aesthetics.

- ESD Polyurethane: Like epoxy but more flexible and UV-resistant, often with a matte or satin finish, ideal for heavy traffic in colors like beige or custom shades.

Imagine a high-tech facility:

- A light gray ESD epoxy floor gleams with a glossy sheen, reflecting lights for a clean, modern vibe.

- A lab features dark gray ESD rubber with a hammered texture, offering comfort and static protection.

- A corridor shines with beige ESD polyurethane, its matte finish enduring heavy use while blending with the decor.

These floors can also be customized with logos, directional arrows, or color zones to enhance both functionality and style. For actual images, search “ESD flooring images” online or visit the websites of brands like Sika, Basf, or Fosroc, which often feature product visuals.